Magmark SS

The Future of Sustainable Packaging for Shrink Sleeves

Transparent. Food-safe. Patented. Magmark SS transforms problematic for recycling shrink sleeves into easily separable components making them ‘preferred’ for recycling

Despite their dominance in the labeling market due to visual appeal and functionality, shrink sleeves pose a major recycling challenge. An inability to separate them during PET bottle recycling contaminates recycled PET flake, rendering the flake unusable for high-quality circular applications such as new bottles.

Magmark SS – A Game Changer for Shrink Sleeve Recycling

Magnomer’s patented magnetizable coatings transform problematic shrink labels into easily recyclable components. Magmark SS leverages existing magnetic sorting technology in recycling infrastructure to achieve remarkable separation rates, paving the way for a truly circular recycling process. Magmark SS coatings are transparent, food-safe, and sync with existing printing operations. They can be applied to both PETG and CPET labels.

Choosing the Right Magmark SS for Your Needs

Core Products

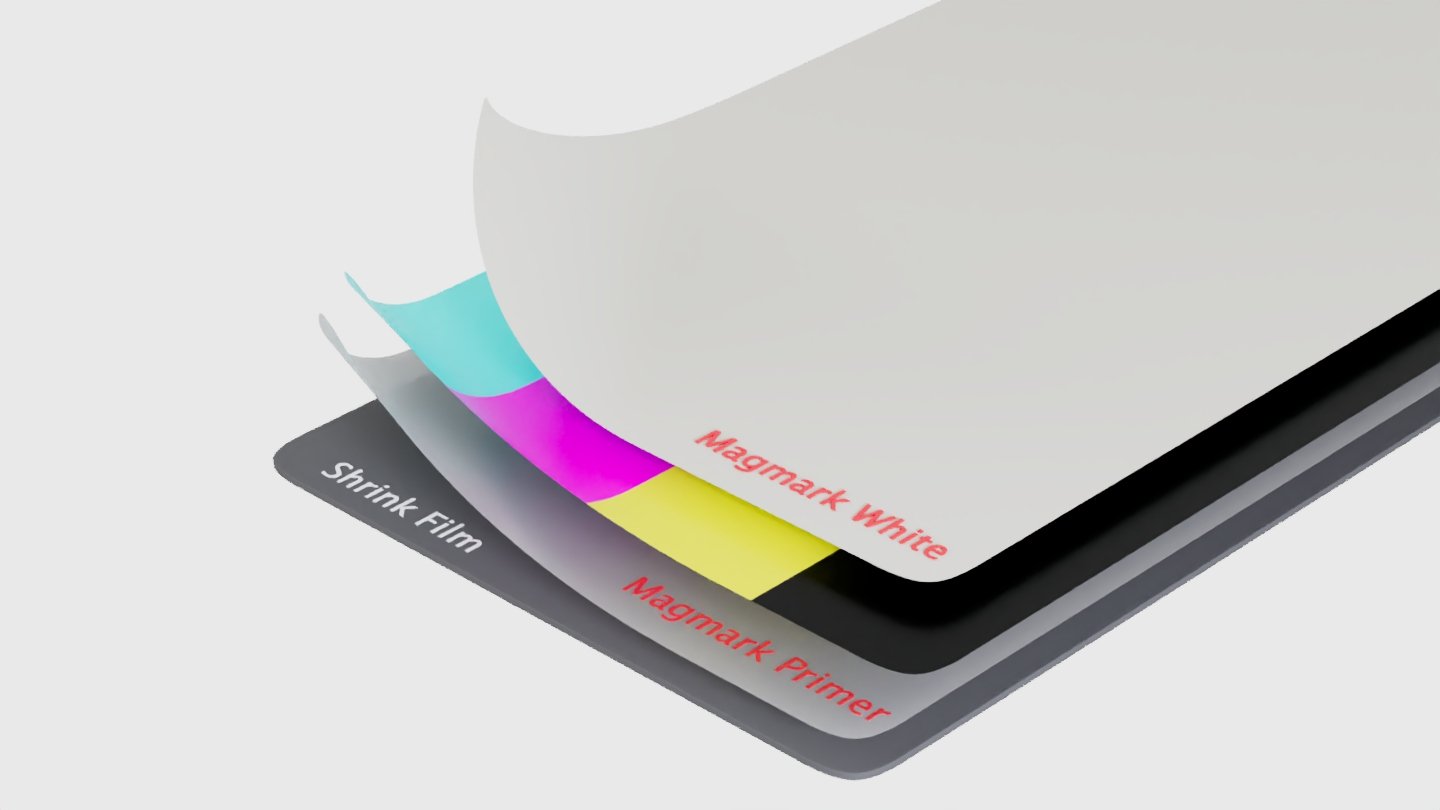

Core products that add magnetization to labels to allow for their separation in recycling operations. These coatings can be applied in primer mode, or in sandwich mode.

Magmark SS Primer

Magmark SS Primer imparts magnetization

Printed as a first coat on the label substrate

Compatible with: Solvent Gravure, Solvent Flexo, UV Flexo

Magmark SS Sandwich

Magmark SS Sandwich imparts magnetization

Printed between the colors and the white

Compatible with: Solvent Gravure

Complementary products

The APR recognition of Magmark SS coatings requires inks to stay on the label through the caustic wash process. Magnomer therefore offers complementary products to add chemical resistance to your existing inks.

Magmark SS Varnish

Magmark SS Varnish is a non-magnetizable coating that imparts chemical resistance

Serves as a replacement for existing varnish

Offers slip to provide the desired coefficient of friction (CoF)

Compatible with: Solvent Gravure, Solvent Flexo, UV Flexo

Magmark SS White

Magarmk SS Whites are non-magnetizable whites designed to impart chemical resistance

Serve as replacements for existing whites Offer slip to provide the desired coefficient of friction (CoF)

Compatible with: Solvent Gravure, UV Flexo

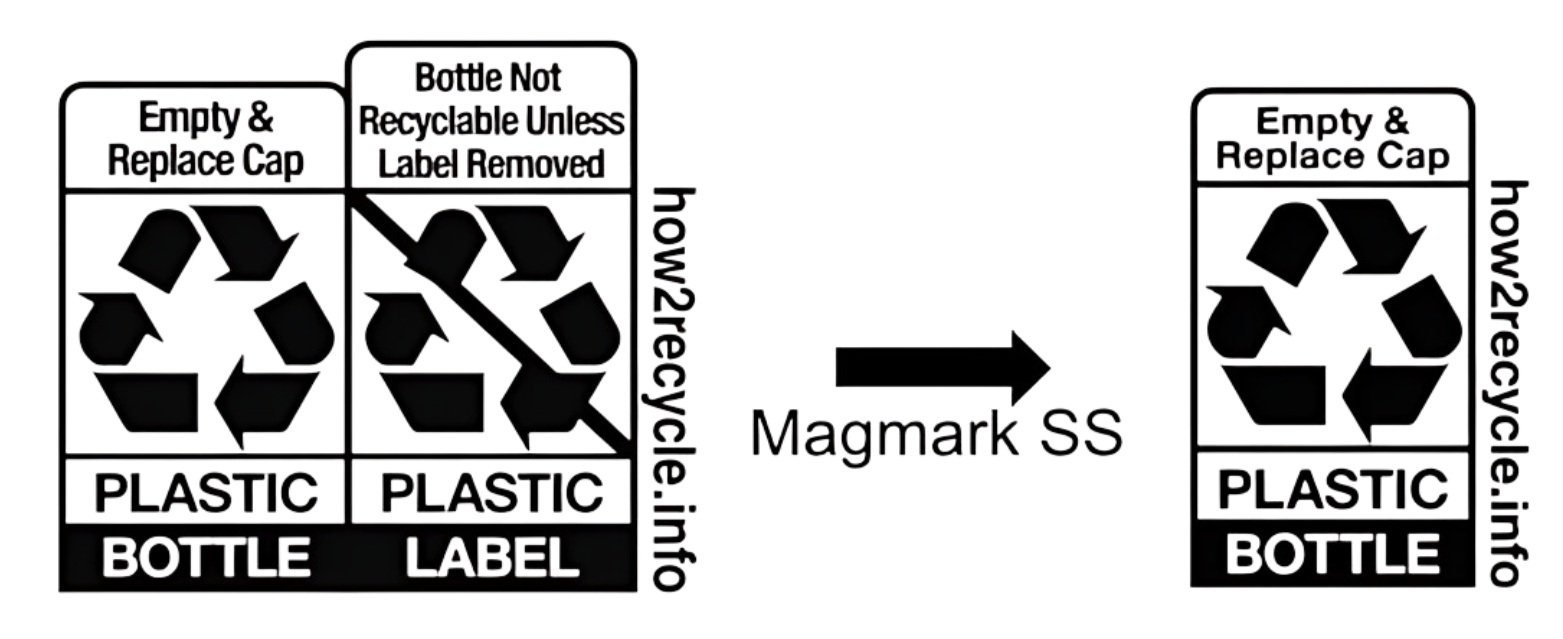

How2Recycle

How2Recycle, part of the non-profit greenblue.org is a standardized labeling system intended to communicate disposal instructions to the public. PETG shrink sleeves on PET bottles are considered detrimental to recycling and typical How2Recycle instructions include removing the shrink label before recycling the bottle. Magmark SS coatings, together with a PETG shrink sleeve and an otherwise recyclable PET bottle, allow the bottle to be considered Optimally Recyclable, which means that no sleeve removal is necessary. This is the first time that a PETG shrink sleeve has been prequalified in this way, and it is Magmark SS that makes the difference.

APR’s Responsible Innovation Recognition

APR Recognized based on high volume tests

The APR Design Guide for Plastic Recyclability outlines guidelines and acknowledges packaging innovations that aid recycling. Commercial scale testing at multiple recyclers showed Magmark coatings enable removal of problematic shrink sleeve labels during PET recycling.

“The Association of Plastic Recyclers is pleased to recognise that Magnomer’s Magmark SS Coating has received the Responsible Innovation Recognition.”

– Steve Alexander, President and CEO, The Association of Plastic Recyclers.

The separation of labels using magnets not only serves the all-important purpose of contamination reduction, but also represents an opportunity to recycle the label itself

-Greg Johnson, Evergreen Recycling

Such innovations which make use of existing equipment to further improve rPET quality are commendable and should be welcomed in the PET recycling industry.

– Byron Geiger, Indorama Venture